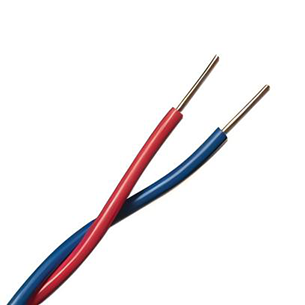

From bare copper wire to Two core fire-resistant cable

Jiangsu Jiacheng Technology Co., Ltd. has been committed to the development of the cable manufacturing equipment industry since its establishment in 1990. We are a professional company that manufactures various types of wire and cable manufacturing equipment such as wire drawing machines, twisting machines, extruder machines, coiling and wrapping machine, stranding machines, annealing and tinning machines and other related wire and cable making machine.

Recently, our company successfully reached a cooperation agreement with a customer in the United Arab Emirates and delivered a complete plan for the production of a 2-core 1.5-2.5 square meter fire-resistant cable production line. During the acceptance process, the customer highly recognized our company's mechanical performance, quality, and various after-sales services, and looks forward to further cooperation with Jiacheng Technology in the future.

This plan was provided to one of our customers from United Arab Emirates ,We went through 4 months from ordering contracts with customers, completing production, customer acceptance, arranging container transportation, arranging engineers for debugging, to finally achieving normal production for the customers

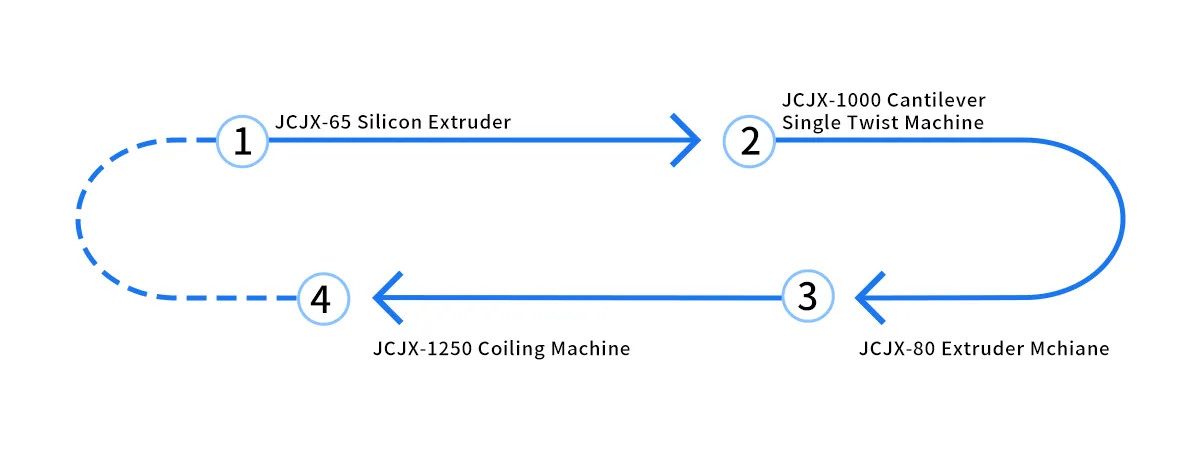

There are a total of four production lines, and the details are as follows:

1.JCJX-65 Silicon Extruder Extrusion of core wire

2.JCJX-1000 Cantilever Single Twist Machine Twisting of core wire

3.JCJX-80 Extruder Extrusion of sheath

4.JCJX-1250 Coiling Machine Coiling

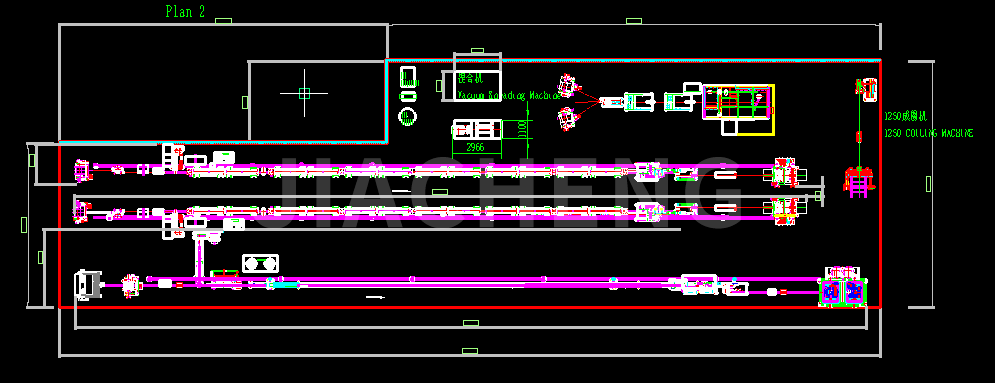

Customer factory planning drawings:

JCJX-65 Silicon Extruder

Applying to all kinds of high temperature silicone rubber cable and high temperature sheaths.

1.PLC+ Touch screen control , adjusting and monitoring parameter of whole production line.

2.Silicone rubber used screw and barrel, crosshead and dies to prevent inner vulcanization.

3.Silicone rubber used avoiding adjusting die-head, water cooling system automatic contaol or manual control.

4.With precision testing feedback system to ensure accurate wire diameter so as to reduce cost.

| model | JCJX-45 | JCJX-70 | JCJX-90 | JCJX-120 |

| Main machine power(kw) | 11 | 22 | 37 | 45 |

| Extrusion capacity(kg/h) | 30 | 80 | 135 | 260 |

| Screw diameter(mm) | φ45 | Φ70 | φ90 | φ120 |

| Screw L/D ratio | 12:1 | 14:1 | 14:1 | 14:1 |

| Pay-off bobbin size(mm) | φ300-400 | Φ400-630 | φ400-630 | φ1000-1200 |

| Conductor sizes(mm) | φ0.2-3.0 | Φ1.5-6.0 | φ2.1-10 | φ5.0-15 |

| Finished cable sizes(mm) | φ0.8-5.0 | Φ1.8-8.0 | φ3.0-12 | φ8.0-20 |

| Vulcanization tank length(m) | 12 | 16 | 24 | 24 |

| Heating power | Section 36kw | Section 48kw | Section 72kw | Section 84kw |

| Traction motor(kw) | 2.2 | 4 | 7.5 | 11 |

| Production speed(m/min) | 10-200 | 10-200 | 4-40 | 4-40 |

| Take-up bobbin sizes(mm) | Φ400-500 | Φ400-630 | φ1250-1600 | φ1250-2000 |

JCJX-1000 Cantilever Single Twist Machine

It is used to all kinds of the cable and wrapping and also used to all kinds of soft conductor and computer cable, ruber cable controlling cable like KVVRP, KVVR, RVV, KVV.

1) More stability, high production efficiency, low noise and easy to operation.

2) It can twist both cable and copper wire.

3) Twisting and wrapping at the same time.

| Model | JCJX-630 | JCJX-800 | JCJX-1000 | JCJX-1250 |

| Pay-off bobbin dia.(mm) | Φ400-Φ500-Φ630 | |||

| Take-up bobbin dia.(mm) | Φ630 | Φ800 | Φ1000 | Φ1250 |

| Applicable wire dia.(mm) | Φ0.6-3.0 | Φ1.0-5.0 | ||

| Main motor power(kw) | 11 | 15 | 15 | 20 |

| Max. lay-up dia.(mm) | Φ15 | Φ20 | Φ25 | Φ30 |

| Twisting pitch(mm) | 20-200 | 30-300 | 30-350 | 30-350 |

| No. of rotate(r/min) | 1000 | 800 | 600 | 550 |

| Take-up tension | Pneumatic tension | |||

| Traversing style | Stepless regulation,according to bobbin rotation speed and reciprocating motion | |||

| Traversing distance(mm) | 2-12 | 3-20 | 3-30 | 3-30 |

| Twisting direction | S or Z Direction free designation | |||

| Wrapping type | Center wire-wrapping or side wrapping | |||

JCJX-80 Extruder

It's used for the insulation of wire &cable with PVC, LDPE, NYLON, TPU. Also it can be equipment with triple co-extrution crosshead and double layer.

1.Production line consist: pay off, main machine, main cabinet, fixed trough, movable trough, accumulator, traction, take-up, spark tester.

2.Optional parts: active pay of, pre-heater, powder machine, diameter-testing laser gauge, LSZH screw, single and dual bobbin take-up,coiling and wrapping machine.

3.Feature: precise design of the screw, durable, non-mucus, not take off chrome, change color quickly, with high capacity, high quality, the concentricity of wire is more than 90%,with high precision ±0.03. With touch screen+PLC control,easy operation, more hommization.

| Type | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Screw Dia.(mm) | Ø30 | Ø40 | Ø50 | Ø60 | Ø70 | Ø80 | Ø90 |

| Screw L/D Ratio | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Extrusion Capacity(kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Extrusion Capacity(kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Extrusion Capacity(kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Main Motor Power | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Total Power | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Finshed Dia.(mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| Pay-off Bobbin Size(mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Pay-off Power | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Haul-off Unit Type | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Haul-off Unit Power | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Accumulater Length(m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Take-up Bobbin Size(mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Take-up Power | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Line Speed(m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimension(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Weight(T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |

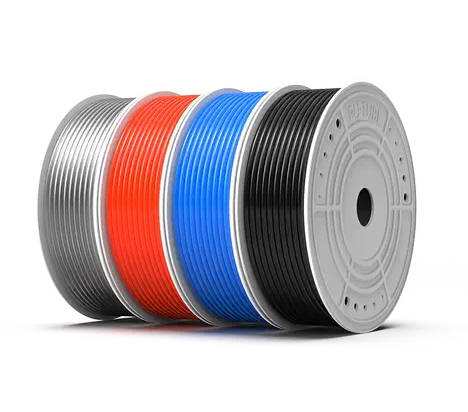

JCJX-1250 Coiling Machine

It is mainly used to roll long rolls of wires or cables into coils to facilitate subsequent packaging, transportation and use.

Feature:

1. The automatic tension can control pay off unit, wires are arranged pertect on the bobbin.;

2. Adopting auto pay off set, pay off wire is in order.

3. High efficiency, generally, produce700 in 8 hours, lift thrice.

| Model | Φ630mm | Φ1250mm | Φ1250-Φ1600mm |

| Applicable wire range | 0.5-6mm2 | 10-70mm2 | 10-240mm2 |

| Traversing tension | Automatically | ||

| Main motor speed | 0-600 r/min | 0-300 r/min | 0-300 r/min |

| Loading bobbin type | Lever-type | Electric type | Electric type |

| Pay-off bibbin model | Φ400-630mm | Φ800-1250mm | Φ1000-1600mm |

| Tapping model | Outside Dia .≤320mm Inner Dia. 120mm Width30-100mm | Outside Dia.≤600mm Inner Dia. 200300mm Width60-150mm 150-200mm | 50-250 |

| Power | 2.2kw | 3kw | 4kw |

| Meter counter structure | Type of wheel pressure | Double wheel type with air pressure | Double wheel type with air pressure |

| Induction type/ Measurement accuracy | Rotary encoder/0.5% | Rotary encoder/0.5% | Rotary encoder/0.5% |