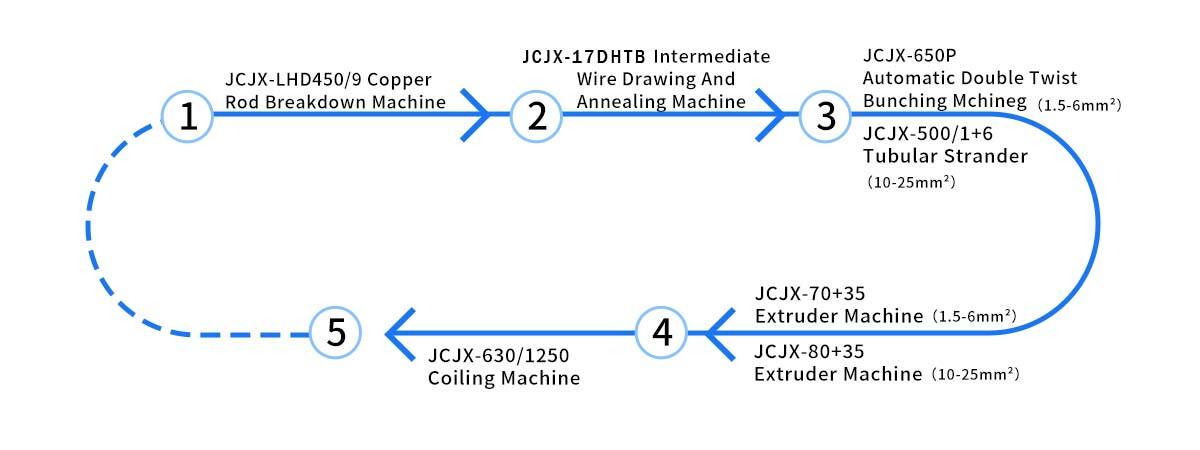

From 8mm copper rod to 1.5-2.5 square single core cable

Jiangsu Jiacheng Technology Co., Ltd. has been committed to the development of the cable manufacturing equipment industry since its establishment in 1990. We are a professional company that manufactures various types of wire and cable manufacturing equipment such as wire drawing machines, twisting machines, extruder machines, coiling and wrapping machine, stranding machines, annealing and tinning machines and other related wire and cable making machine.

Recently, a 1.5-2.5 square meter single core cable production line was delivered in Ghana. After six months, from the determination of the plan to the completion of machine production, to customer acceptance, and finally to the completion of engineer debugging, the machine has been running normally and the factory has started production. Ghanaian customers have given high praise to our machines, recognizing both their performance and after-sales service. Jiacheng's machines have been exported to more than 100 countries overseas, and Jiacheng is willing to serve different wire and cable manufacturers around the world.

This plan was provided to one of our clients from Ghana:

Starting from signing the contract with our customer,

Completing the machine production and customer acceptance,

Arranging containers transportation,

Arranging engineers for debugging

About 6 months later, our customer started their normal production.

There are a total of seven production lines as shown in the following figure:

1.JCJX-LHD450/9 Copper Rod Breakdown Machine

2.JCJX-17DHTB

3.JCJX-650P Automatic Double Twist Bunching Machine

4.JCJX-500/1+6 Tubular Strander

5.JCJX-70+35 Extruder Machine

6.JCJX-630 Coiling Machine

7.JCJX-1250 Coiling Machine

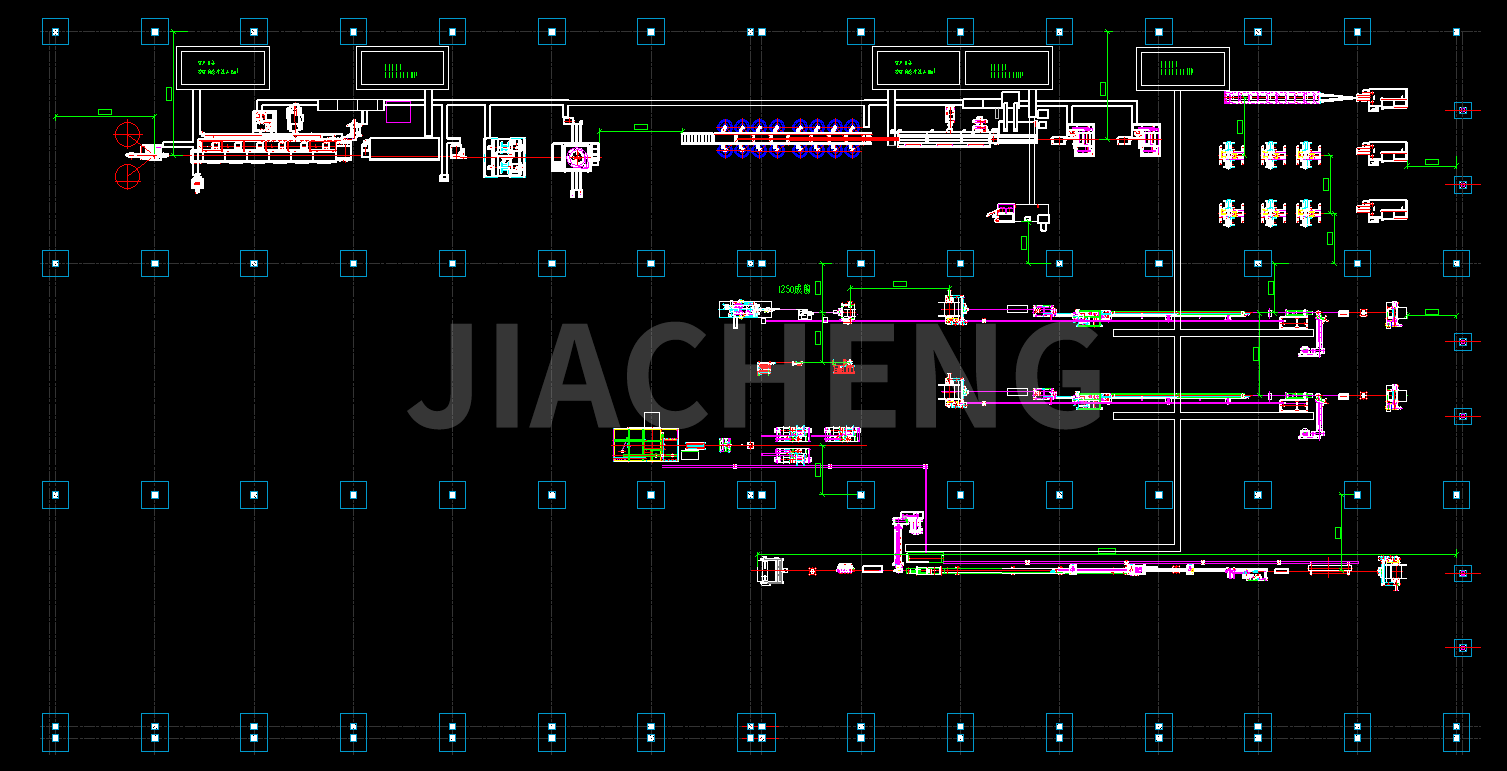

Customer factory planning drawings

JCJX-LHD450/9

The LHT450 Copper Rod Breakdown Machine is a drawing equipment that draws copper wire with a diameter of 8mm to 1.2mm-4.0mm. It has an iron cast gearbox body, operates with low noise, and is coated with tungsten carbide on the surface.

Maximum inlet diameter: Φ 8mm

Output diameter: Φ 1.2mm~ Φ 4.0mm, Φ 1.5mm~ Φ 4.0mm, Φ 2.1mm~ Φ 4.0mm.

| Machine Type | LHT450/13 | LHT450/11 | LHT450/9 |

| Max.Inlet Dia.(mm) | φ8 | φ8 | φ8 |

| Outlet Dia.(mm) | φ1.2-4.0 | φ1.5-4.0 | φ2.1-4.0 |

| Max.Die No. | 13 | 11 | 9 |

| Max. line speed(m/s) | 25 | 22 | 20 |

| Body structure | Ironed cast | ||

| Transmission type | By high precision grinding gear | ||

| Fix speed capstan Dia.(mm) | Fix speed capstan Dia.(mm) | ||

| Drawing capstan | φ450 | ||

| Main motor power(KW) | Coated by tungsten | ||

| Fix speed capstan motor(KW) | 280 | ||

| Lubrication type | 75 | ||

| Lubrication type | Immersion | ||

| Optional equipment | 1. 450T continuous annealing device 2. Double rake-up 3. Coiler 4、WS-1000 take-up | ||

JCJX-17DHTB

The drawing speed is between high-speed and low-speed wire drawing machines. It is equipped with a continuous annealing device, which can perform online heat treatment on the wire during the drawing process to remove work hardening and restore the plasticity of the metal.

1. Double inverters auto tension control system.

2. Unify 250 cast-iron main frame, precision machinery, no shock.

3. Capstan treated with wear-resistant tungsten.

4. Suitable for continuous annealer, take up machine with and without shaft , coiler machine.

| Machine type | 280/13DH | 300/9DH | 250/17DH | 260/17D |

| Max. Inlet Dia.(mm) | Φ3.5 | |||

| Outlet Dia.(mm) | Φ0.65-2.80 | Φ1.2-2.8 | Φ0.4-1.6 | Φ0.4-1.2 |

| Max. Die No. | 13 | 9 | 17 | 17 |

| Max. Line Speed(m/min) | 2000 | 1200 | 1800 | 1200 |

| Body Structure | ironed cast | |||

| Slip ratio of machine | 20% | 18% | 20% | 18% |

| Transmission Type | 280 | 300 | 250 | 260 |

| Fixed Speed Capstan Dia.(mm) | By high precision grinding gear | By chain | ||

| Take-up Motor Power(KW) | 11(15) | 11 | ||

| Lubrication Type | Full immersion | Spray type | ||

| Take-up Bobbin Size(mm) | Φ500/Φ630(Bore is Φ127mm) or changed by requirement | |||

| Optional Equipment | 1.Continuous annealing device 2.Coiler | |||

| On-line Continous Annealing Device | |||

| Type | 350T | 250T/B | 250T/A |

| Machine Structure | Horizontal | Vertical | Vertical |

| Annealing Wheel Dia.(mm) | Φ350 | Φ250 | Φ250 |

| Annealing Wire Dia.(mm) | Φ0.8-Φ2.8 | Φ0.6-Φ2.2 | Φ0.4-Φ1.6 |

| Annealing Protection Type | Steam or Nitrogen | ||

| Annealing Votage | 0-65V(DC) | 0-60V(DC) | |

| Annealing Current | 0-2500A(DC) | 0-(2000A,1500A,1200A)(DC) | |

JCJX-650P Automatic Double Twist Bunching Machine

It is adapt to twist the bare copper wire, tin-coating wire and varnished wire which are more than 7 strands, Magnetic brake, which brake automatic when wire break, tension adopts magnetic powder clutch type.(PLC control output).

1. Transducer adopts INOVANCE brand, Bearings are imported brands.

2. The motor adopts the national first-class brand

3. Low voltage on-off, brake adopt the top grade brand home and abroad.

| Machine Type | JCJX-300P | JCJX-500P | JCJX-500PB |

| Use | For bunching 7 bare copper, tinned wire,enameled wire | ||

| Control Type | PLC+HMI+Inverter control | ||

| Twisting Section area(mm2) | 0.035-0.45 | 0.05-2.50 | 0.05-4.00 |

| Copper Wire Dia.(mm) | Φ0.05-Φ0.25 | Φ0.10-Φ0.45 | Φ0.10-Φ0.52 |

| Twisting Pitch(mm) | 2.00-17.17 | 6.30-50.40 | 6.30-80.5 |

| Twisting Direction | S or Z | ||

| Take-up Tension | Tension Controlled by magnetic clutch | ||

| Max Main Shaft Speed(r/min) | 3000 | 3000 | 2500 |

| Traversing Type | Transverse and distance can be adjusted by bearing transverse | ||

| Bearing Lubrication | Lubricating nipple with high temperature oil | Thin oil lubrication, circulation cooling | |

| Bobbin Loading&Unloading Type | Hydraulic type | ||

| Max. Bobbin Dia. | Φ300 | Φ500 | Φ500 |

| Auto Stop Unit | Auto stop while reach setting length,and wire broken inside and outside | ||

| Brake | Magnetic brake | ||

| Motor Power(kw) | 4 | 5.5 | 5.5 |

| Main Shaft Center Height(mm) | 630 | 700 | 700 |

JCJX-500/1+6 Tubular Strander

The machine is used to make copper stranded wire,steel-core aluminium stranding wire andsteel rope.It also can be used to stranded steel wire and insulated wire.

According to different models, the maximum twisting outer diameter can be selected: 12mm and 15m According to different models, the range of twist pitch is 20~181, 20~331, 36~274

1. Operate convenient,PLC+HMI+inverter control.

2. Low cost and high efficiency.

3. High speed,high capacity.

4. This machine is used to make copper stranded wire, steel-core aluminium stranding wire and steel rope.It also can be used to stranded steel wire and insulated wire.

| Machine type | 400 type | 500 type | 630 type |

| Single copper wire diameter | Ø1.0-2.5mm | Ø 1.3-4.5mm | |

| Single steel wire diameter | Ø1.5-3.0 | Ø1.3-3.5mm | |

| Single aluminum wire diameter | Ø1.5-4.0mm | Ø1.8-5mm | |

| Max stranded dia. | 12mm | 15mm | |

| Pitch range | 20-181mm | 20-331mm | 36-274mm |

| Tube rotate speed | 700r/min | Large bearing type 600r/min | Large bearing type 500r/min |

| Supporting wheel 500r/min | Supporting wheel 350r/min | ||

| Traction wheel dia | Ø800+400mm | Ø1250mm | Ø1250mm |

| Pay-off bobbin inside of strander | 400mm | 500mm | 630mm |

| Take-up bobbin size | PN800-1250mm | PN800-1600mm | PN1200-2000mm |

JCJX-70+35 Extruder Machine

Precise design of the screw, durable, non-mucus, not take off chrome, change color quickly, with high capacity, high quality, the concentricity of wire is more than 90%, with high precision ±0.03. With touch screen+PLC control, easy operation, more hommization.

1. Usage: it's used for the insulation of cable with PVC, LDPE,NYLON,TPU.

2. Production line consist: pay off, main machine, main cabinet, fixed trough, traction, take-up.

3. Optional parts: caterpillar, sparkling machine, diameter-testing laser gauge, LSZH screw, gantry type take-up and pay off, end-shaft type take-up and pay off.

| Type | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Screw Dia.(mm) | Ø30 | Ø40 | Ø50 | Ø60 | Ø70 | Ø80 | Ø90 |

| Screw L/D Ratio | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Extrusion Capacity(kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Extrusion Capacity(kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Extrusion Capacity(kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Main Motor Power | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Total Power | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Finshed Dia.(mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| Pay-off Bobbin Size(mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Pay-off Power | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Haul-off Unit Type | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Haul-off Unit Power | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Accumulater Length(m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Take-up Bobbin Size(mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Take-up Power | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Line Speed(m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimension(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Weight(T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |

JCJX-630/1250 Coiling Machine

It is mainly used to roll long rolls of wires or cables into coils to facilitate subsequent packaging, transportation and use.

Feature:

1. The automatic tension can control pay off unit, wires are arranged pertect on the bobbin.;

2. Adopting auto pay off set, pay off wire is in order.

3. High efficiency, generally, produce700 in 8 hours, lift thrice.

| Model | Φ630mm | Φ1250mm | Φ1250-Φ1600mm |

| Applicable wire range | 0.5-6mm2 | 10-70mm2 | 10-240mm2 |

| Traversing tension | Automatically | ||

| Main motor speed | 0-600 r/min | 0-300 r/min | 0-300 r/min |

| Loading bobbin type | Lever-type | Electric type | Electric type |

| Pay-off bibbin model | Φ400-630mm | Φ800-1250mm | Φ1000-1600mm |

| Tapping model | Outside Dia .≤320mm Inner Dia. 120mm Width30-100mm | Outside Dia.≤600mm Inner Dia. 200300mm Width60-150mm 150-200mm | 50-250 |

| Power | 2.2kw | 3kw | 4kw |

| Meter counter structure | Type of wheel pressure | Double wheel type with air pressure | Double wheel type with air pressure |

| Induction type/ Measurement accuracy | Rotary encoder/0.5% | Rotary encoder/0.5% | Rotary encoder/0.5% |