Double Intermediate Wires Drawing Machine

| Brand Name: | JIACHENG |

| Model Number: | JCJX-9DH-2 JCJX-13DH-2 JCJX-17DH-2 |

| Certification: | CE/ISO9001:2008 |

| Price: | Negotiation |

- Quick Detail

- Description

- Applications

- Specifications

- Company

Quick Detail

The double-head middle drawing machine is designed to draw two wires at the same time, which can significantly improve production efficiency, especially when producing large quantities.Usually equipped with automated systems that can automatically complete the processes of wire loading, drawing, cooling and winding.

Input diameter: 2.5mm~3.5mm

Output diameter range: from 0.4mm to 1.8mm depending on the model

Description

1. Main Drawing Machine, used to drawing 2 copper wire from 2.5-3.5mm to 0.4-1.8mm.

2. The machine has 3 type for choose, JCJX-13DH-2 (13 dies, output 1.0-1.8mm) , JCJX-9DH-2 (9 dies, output 0.68-1.2mm) , JCJX-17DH-2 (17 dies, output 0.4-1.0mm) , you can choose the machine according the outlet diameter.

3. The machine body structure is ironed cast. 2 layers door design for better protection.

4. The tranmission type is high precision gear transmission, high efficiency, low noise.

5. Wire Drawing Machine Production Line consist: pay off, main drawing machine, tension stand, QD630 take up.

6. Optional Parts: annealing, coiler.

7. Double inverters auto tension control system.

8. Unify 250 cast-iron main frame, precision machinery, no shock.Capstan treated with carbon fiber.

9. Suitable for continuous annealer, take up machine with and without shaft

colier machine.

10. 2 wires design with the function of double capacity, power-saving, room-saving, labor -saving.

Applications

This machine is suitable for manufacturing plants, especially in the cable industry, for efficient continuous production.

Specifications

| Machine Type | JCJX-9DH-2 | JCJX-13DH-2 | JCJX-17DH-2 |

| Drawing Wire NO. | 2Wires | ||

| Max. Inlet Dia.(mm) | Φ2.5-Φ3.5 | ||

| Outlet Dia.(mm) | 2xΦ1.0-Φ1.8 | 2xΦ0.68-Φ1.2 | Φ0.4-Φ1.0 |

| 1x2.8 max. | 1x2.8 max. | 1x2.0 max. | |

| Max. Die No. | 9 | 13 | 17 |

| Max. Line Speed(m/min) | 1200 | 2000 | 2000 |

| Body Structure | Ironed Cast | ||

| Drawing Capstan | Carbon Fiber and Tungsten Plasma Capstan | ||

| Main Motor Power(KW) | 75 | ||

| Take-up Motor Power(KW) | 15 | ||

| Capstan Dia.(Max.)(mm) | Φ300 | Φ280 | Φ250 |

| Fix Speed Capstan Dia.(mm) | Φ300 | Φ280 | Φ250 |

| Transmission Type | By gear | ||

| Lubrication Type | Full Immersion | ||

| Tension Control | Air Pressure Type | ||

| Take-up Type | Shaftless Type | ||

| Take-up Bobbin Size | Φ500(boreΦ127) Φ630(bore Φ127) | ||

| Traversing Type | Gear Motor Type | ||

| Brake | Disc Brake | ||

| On-line Continous Annealing Device | ||

| Type | 350T-2 | 250TB-2 |

| Machine Structure | Horizontal | Vertical |

| Annealing Wire Dia.(mm) | 2xΦ0.8-Φ1.8 1x2.8 max. | 2xΦ0.4Φ1.2 1x2.0 max. |

| Annealing Votage | 0-60V | 0-60V |

| Annealing Current | 0-4000A | 0-3000A |

Company

Jiangsu Jiacheng Technology Co.,Ltd, was founded in 1990,which is located in the beautiful and newly developed city ZhangJiaGang. It is close to the north of the Shanghai-Nanjing expressway, the east is Shanghai and the north is Nantong. The land-and-water transportation is convenient.The occupied area of the company is 28,800 square meters, with 9 layers office building and multiple workshops that are modern and standardized. It is a professional manufacturer in making all kinds of Wire Drawing Machines, Twisting Machines, Extruder Machines, Coiling and Wrapping machine, Stranding Machines, Annealing and Tinning Machines and other related wire and cable making machines. JIACHENG's technical team formed by many experts and engineers from China and worldwide. Our company is concentrated on making high quality Wire and Cable Making Machines. And our products have exported to more than 100 different countries around the world, such as Italy, Spain, Britain, Brazil, Vietnam, Algeria, Nigeria, Türkiye, South Africa, Egypt, Russia, India, Pakistan etc. At the same time, we are able to provide customer 24/7 After-sale customer service for our customer. We would like to serve all worldwide customers with our JIACHENG's warmest heart.

Certificate

Workshop Pictures

Exhibition

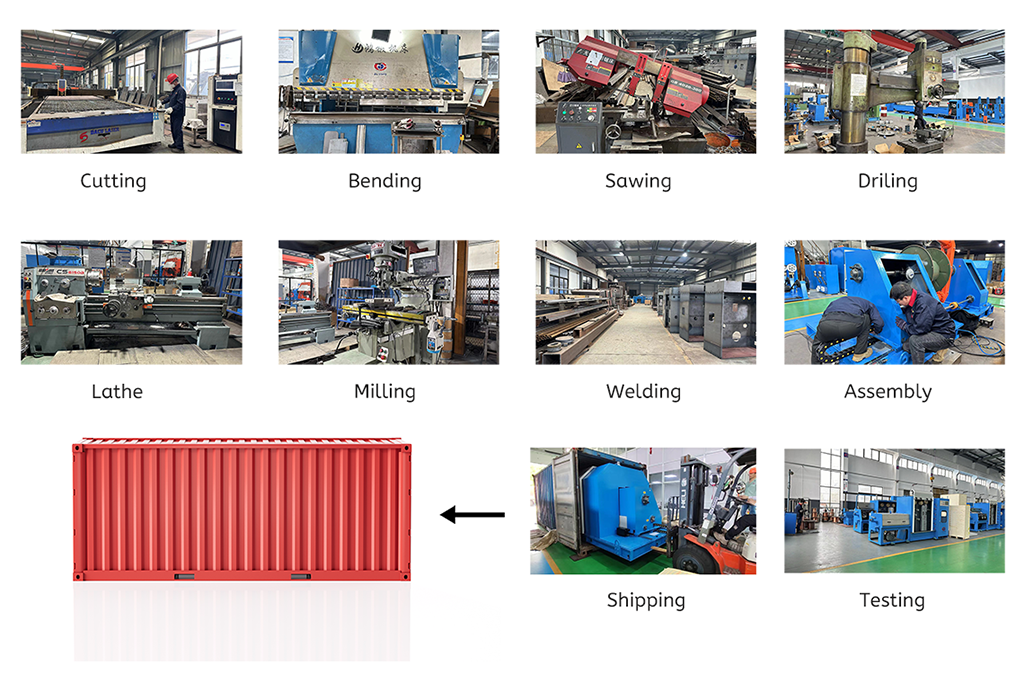

Production Srocess

Production

Team

FAQ

Q:I just get into this industry, I don't know how to plan?

A:Every salesman of us can tell you how to plan the workshop ,how to install the equipment,how to save the costs and so on.

Q:How can i install my machine when it arrives?

A:We will send our engineers to your factory to install the machines and train your staff how to operate the machines

Q:How could find the most suitable machine?

A:Tell us your request in details: inlet wire and out wire diameter range, production capacity.

Q:How could find the reliable supplier?

A:1)Check the background information which is assured and certificated.

2) Visit the factory, have a face to face meeting.

Q:Why there are big differences price between different suppliers?

A:After visiting factory, compare the price based on same quality and service.

Q:Are you trading company?

A:No, we are professtional wire and cable machinery manufacturer since 2001.

Q:What kind of machine do you have?

A:We can offer from Cu, Al RBD machine, intermediate wire drawing machine, fine wire drawing machine, multi wire drawing machine,tinning and annealing machine, double twist bunching machine, cable stranding machine, pvc cable extruder etc.

Q:How can we go to your factory?

A:Our company is located in Zhangjiagang city, 2.5 hours to Pudong airport, 1.5 hours to Hongqiao airport, 1 hour to Wuxi airport.

Q:If we buy machine from you, can you offer some raw material and spare part?

A:Yes, for example, if you buy cable extruder from us, we can also offer you the bobbin,cable mold, and pvc raw material ect.

Q:Which industries are mainly targeted at JIACHENG's equipment?

A:Wire and cable, enameled wire, electron beam, cutting line, magnetic wire,and S.S.wire etc.